Kynning á 4 Kjarna snúrur með loftræstikörum

Undanfarin ár, 4 kjarna snúrur með loftræstikerfi hafa komið fram sem nauðsynlegir þættir á sviði verkfræðinnar, sérstaklega í notkun sem tengist mælingu á vatnsþrýstingi og uppgötvun vökvastigs. Þessir sérhæfðu snúrur eru hannaðar til að veita áreiðanlegar og nákvæmar mælingar á ýmsum vökvabreytum, sem skiptir sköpum fyrir fjölmargar atvinnugreinar, þar á meðal smíði, Umhverfiseftirlit, og stjórnun vatnsauðlinda. Mikilvægi þessara snúru liggur ekki aðeins í uppbyggingarhönnun þeirra heldur einnig í virkni þeirra, sem samþættir háþróaða tækni til að auka árangur.

Aðal uppbygging a 4 Kjarnasnúran inniheldur venjulega fjóra leiðara sem gera kleift að senda gögn sem tengjast rafmerkjum sem myndast af þrýstingskynjara. Að taka upp loftræstikerfi auðveldar samskiptin við þrýstingsbreytara á þann hátt sem bætir upp sveiflur í andrúmsloftinu. Þessi hönnun er sérstaklega mikilvæg í umhverfi þar sem vatnsborð og þrýstingur getur breyst hratt vegna umhverfisaðstæðna. Þar sem vatnsatvik eru oft háð afbrigði af andrúmsloftinu, Notkun snúrur með loftræstikerfi tryggir að mælingar haldist nákvæmar og áreiðanlegar, þannig að forðast hugsanleg gögn ónákvæmni.

Þessir snúrur eru mikið notaðir í atburðarásum, allt frá því að fylgjast með vatnsborðum í lóninu, til að stjórna þrýstingi í iðnaðarvatnskerfi. Með því að viðhalda stöðugum viðmiðunarþrýstingi í gegnum loftræstingarrörin, Verkfræðingar geta fengið raunhæfar mælingar sem upplýsa ákvarðanatökuferli. Ennfremur, fjölhæfni 4 kjarna snúrur gerir þeim kleift að nota í ýmsum innsetningar, Frá yfirborðsstigum til djúpra holukerfa, efla gagnsemi þeirra á ýmsum verkfræðisviðum.

Að lokum, Að skilja mikilvægi 4 Kjarnasnúrur með loftræstikerfi eru nauðsynlegir fyrir fagfólk sem stundar verkfræði og umhverfisvísindi, Þar sem þessir snúrur bæta ekki aðeins mælingu nákvæmni heldur auðvelda einnig árangursríka stjórnun og eftirlit með vatnsauðlindum.

Að skilja mælingu vatnsþrýstings

Mæling á vatnsþrýstingi er mikilvægur þáttur í ýmsum atvinnugreinum eins og vatnsfræði, pípulagnir, og umhverfisvöktun. Hugmyndin snýst um að skilja kraftinn sem vatni beitir, sem getur haft veruleg áhrif á skilvirkni kerfisins og öryggi. Þrýstingsmæling lýtur fyrst og fremst um að mæla þrýstinginn í vatnskerfi, Venjulega mælt í pundum á fermetra tommu (Psi) eða pascals (Pa). Auk þess, Nákvæmar aflestrar skipta sköpum til að fylgjast með heilleika vatns afhendingarkerfa og tryggja að þrýstingsgildi haldist innan öruggrar rekstrarþols.

Nokkrar tegundir skynjara eru notaðar til að mæla vatnsþrýsting, með hverjum og einum sem hefur sérstaka kosti eftir því hvaða umsókn. Algengar skynjarategundir fela í sér piezoresistive, rafrýmd, og álagsmælisskynjarar. Piezoresistive skynjarar eru sérstaklega metnir fyrir nákvæmni þeirra og svörun, Að gera þær hentugar fyrir forrit sem krefjast nákvæmra þrýstingsmælinga. Rafrýmd skynjarar bjóða upp á aðra nálgun, þar sem þeir mæla þrýsting út frá breytingum á þéttni, meðan álagsmælisskynjarar virka með því að mæla röskun í efni undir þrýstingi. Hver skynjara tegund veitir einstaka ávinning hvað varðar næmi og áreiðanleika, leyfa sérsniðnar lausnir byggðar á sérstökum rekstrarkröfum.

Til að auðvelda árangursríka gagnaflutning frá þessum skynjara yfir í eftirlitskerfi, 4 Kjarna snúrur eru oft notaðir. Þessir sérhæfðu snúrur samanstanda af fjórum leiðara, sem auka samskipta getu með því að leyfa samtímis sendingu margra merkja. Hönnun 4 kjarna snúrur, oft felld með loftræstikörum, Tryggir að öllum þrýstingsafbrigðum sem skynjarinn uppgötvast sé nákvæmlega og skilvirkt miðlað til eftirlitskerfanna. Þessi óaðfinnanlegur flutningur gagna er nauðsynlegur til að koma á yfirgripsmiklu yfirliti yfir vatnsþrýstingsskilyrði. Nákvæmar vatnsþrýstingslestrar gegna mikilvægu hlutverki við að koma í veg fyrir bilun í kerfinu, Hagræðing á aðgerðum, og tryggja samræmi við reglugerðarstaðla í ýmsum greinum.

Mikilvægi loftræstikerfis í snúruhönnun

Loftræstikerfi gegna mikilvægu hlutverki í heildarvirkni 4 kjarna snúrur, sérstaklega þeir sem hannaðir eru fyrir mælingu á vatnsþrýstingi. Þessar slöngur þjóna sem nauðsynlegir þættir sem gera kleift að ná nákvæmri jöfnun andrúmsloftsþrýstings innan kerfisins. Í uppsetningum þar sem mæling á vökvastigi er nauðsynleg, svo sem í vatnsstjórnunarkerfi, Tilvist loftræstikerfis skiptir sköpum fyrir að skynjarar og transducers geti skilað nákvæmum upplestrum.

Aðalaðgerð loftræstingarrör er að leyfa loft að komast inn í snúruna, sem hjálpar til við að koma jafnvægi á innri og ytri þrýstinginn sem beitt er á skynjunarbúnaðinum. Þegar vökvi hækkar eða fellur innan mælitækisins, breytileiki í þrýstingi kemur fram. Án loftræstunar, Þessar breytingar geta leitt til rangra upplestra, as the pressure differential may cause the sensors to respond inaccurately. By equalizing pressure, vent tubes help to mitigate these discrepancies, resulting in reliable and consistent fluid level measurements.

Ennfremur, vent tubes are instrumental in preventing the build-up of negative pressure, which can adversely affect the performance of the pressure measurement system. In fluctuating environmental conditions, such as during heavy rainfall or rapid evaporation, ensuring that pressure levels remain stable is crucial. Vent tubes facilitate this stability by allowing for the escape of trapped air and moisture, thereby reducing the risk of pressure-related measurement errors that may otherwise compromise the data collected.

Í stuttu máli, the incorporation of vent tubes in the design of 4 core cables enhances the accuracy and reliability of water pressure measurement systems. By effectively equalizing pressure and preventing atmospheric interference, these tubes ensure that measurement instruments operate efficiently, even in diverse and changing environmental conditions.

Mechanical Properties and Environmental Resistance

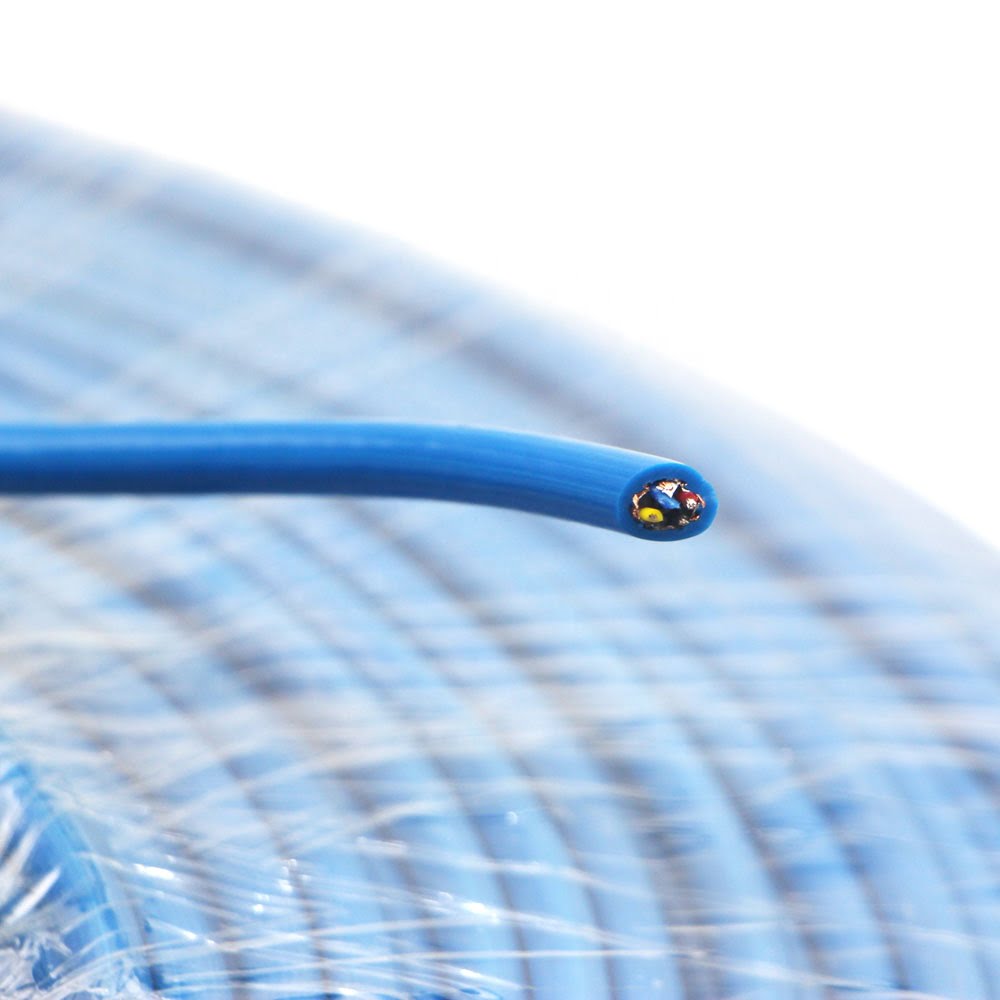

4 core cables with vent tubes are engineered to exhibit exceptional mechanical properties, making them ideal for various applications, particularly in challenging environments such as sewer and cleaning water systems. One of the standout features of these cables is their high mechanical resistance, which allows them to withstand significant physical stress without compromising their integrity. This durability is crucial in scenarios where cables may experience abrasions or impacts from external elements, ensuring consistent performance over time.

Another key attribute of 4 core cables is their flexibility. This characteristic facilitates easier installation and routing through tight spaces, which is often a requirement in sewer systems or cleaning infrastructure. The flexibility of these cables enables them to bend and contour around obstacles, ensuring that they can be deployed in a manner that minimizes stress points and potential failure points. This adaptability is beneficial in applications where traditional cabling might not be viable due to the non-linear layouts of sewage and water systems.

Þar að auki, 4 core cables display significant environmental resistance, which is fundamental in settings exposed to harsh chemicals and varying temperatures. The materials used in manufacturing these cables are designed to resist corrosion and degradation caused by exposure to toxic substances often found in wastewater or cleaning solutions. As a result, they maintain their functionality and longevity, providing reliable operation even in the most adverse conditions. The combination of mechanical strength and environmental resilience renders these cables an optimal choice for professionals focused on ensuring efficient water pressure measurement in challenging settings.

Electrical Specifications and Safety Standards

When discussing 4 core cables with vent tubes used for water pressure measurement, understanding their electrical specifications is paramount. These cables are designed to operate effectively under specific conditions, including an operating voltage typically ranging from 300V to 600V. This voltage rating ensures that the cables can handle the electrical demands common in water pressure measurement systems without compromising safety or functionality.

Another crucial specification is insulation resistance, which usually exceeds 1000 megohms at 500V DC. High insulation resistance plays a significant role in preventing electrical leakage, promoting overall system efficiency, and ensuring user safety. In addition to these core specifications, the cables often exhibit characteristics such as low capacitance, which further enhances signal integrity and reduces interference in measurement outputs.

Adhering to established safety standards is vital in the application of these cables. Cables designed for pressure measurement in water systems must comply with relevant national and international safety guidelines, such as IEC 60529, which addresses the degree of protection provided by enclosures (IP ratings). Ensuring proper insulation, moisture resistance, and cable integrity prevents potential hazards, including short circuits and electrical fires.

Þar að auki, these specifications contribute to the longevity and reliability of the cables in demanding environments. Til dæmis, exposure to water and other harsh conditions can degrade inferior products quickly. Þess vegna, choosing cables with robust insulation and protective features is essential for maintaining operational effectiveness in water pressure measurement applications. Á heildina litið, a comprehensive understanding of the electrical specifications and adherence to safety standards guarantees the safe and efficient functioning of 4 core cables with vent tubes.

Core Configuration and Color Coding

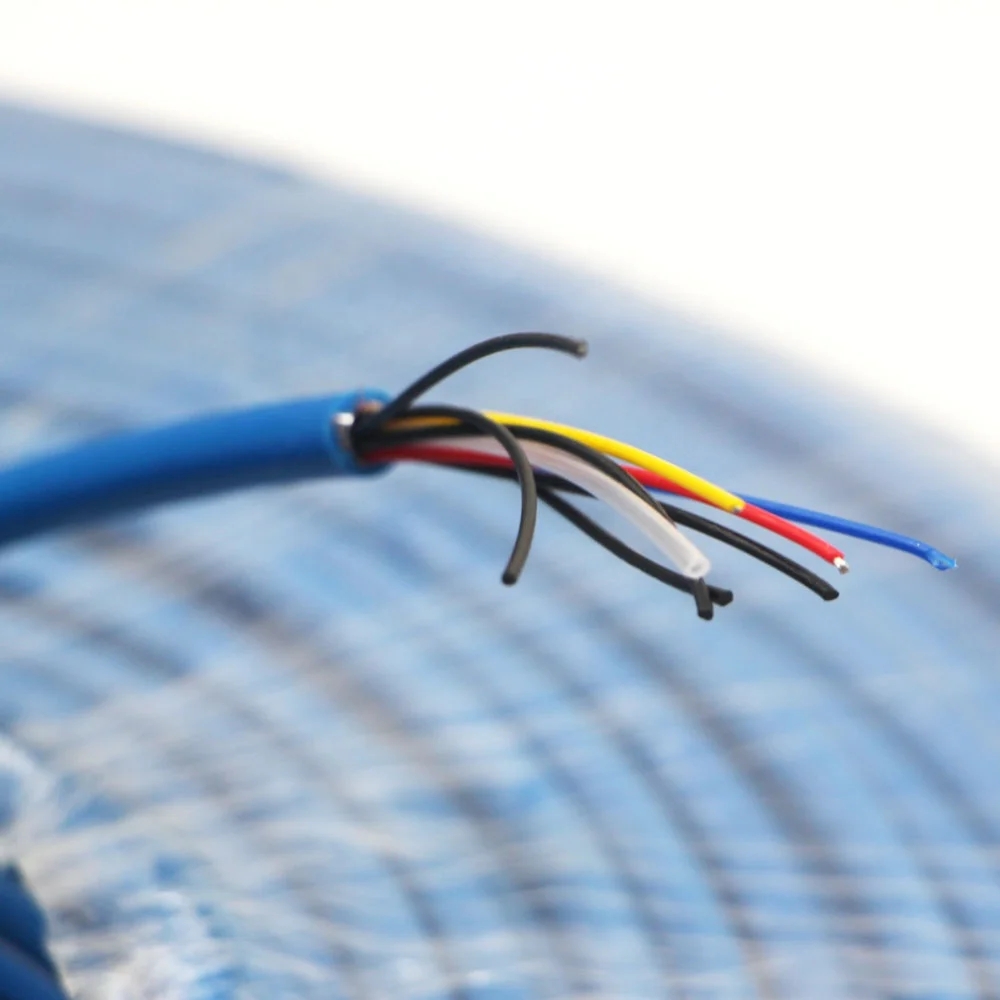

The core configuration of 4 core cables with vent tubes used for water pressure measurement plays a critical role in ensuring accurate data transmission and efficient operation of the associated sensors. These cables typically feature conductors with a cross-section that is optimized for both flexibility and conductivity. The choice of the conductor’s size impacts the cable’s electrical resistance, allowing for minimal signal loss and increased responsiveness. For effective performance, the cross-sectional area must be sufficient to carry the expected load without overheating. Þannig, manufacturers often recommend specific conductor sizes based on the anticipated range of water pressure measurements.

In addition to the conductor cross-section, the color coding of the cables significantly enhances the usability and safety of these components during installation and maintenance. The standard color scheme employs four distinct colors: red, grænn, hvítur, and black. Each color is designated a specific function to streamline the identification process. Til dæmis, the red conductor typically correlates with positive voltage supply, ensuring that users can easily connect the cable to the appropriate terminal without confusion. Green often represents the ground connection, which is crucial for safety and the prevention of electrical shocks.

Meanwhile, the white conductor is generally utilized for sensor signal transmission, facilitating data transfer to the monitoring system. The black conductor typically serves as the negative or return path for the circuit. This systematic color coding not only minimizes installation errors but also aids technicians during troubleshooting and maintenance activities. As a result, the clear identification of functions through color coding contributes to the reliability and efficiency of water pressure measurement systems. Á heildina litið, understanding both the core configuration and the associated color coding is essential for anyone involved in the installation or maintenance of these specialized cables.

Operating Conditions and Temperature Ranges

The operational effectiveness of 4 core cables with vent tubes largely hinges on the environmental conditions and temperature ranges within which they are deployed. These cables are engineered to withstand a diverse array of operating scenarios, making them suitable for various applications, particularly in water pressure measurement systems. Specifically, these cables exhibit remarkable durability under extreme temperatures that range from -30℃ to 75℃. This versatility ensures reliable performance in diverse environments, whether in frigid outdoor conditions or in relatively hot industrial settings.

Maintaining operational integrity under such temperature variations is vital for long-term applications, particularly in fields such as environmental monitoring, industrial settings, and civil engineering. At temperatures as low as -30℃, the physical and electrical properties of the cables remain intact, thereby preventing failures and ensuring consistent readings. Similarly, at elevated temperatures up to 75℃, the integrity of the 4 core cables is preserved, allowing them to function efficiently in high-stress environments aimed at precise water pressure measurements.

Þar að auki, these cables’ resistance to environmental factors such as humidity, abrasion, and chemical exposure contributes to their overall reliability and lifespan. The incorporation of vent tubes further enhances this design by preventing moisture ingress, which is crucial for maintaining the function of the underlying sensors. As a result, applications involving these cables can be deployed in varied locations, including underground installations and exposed outdoor environments, without compromising performance. Understanding these operating conditions and temperature ranges is essential for professionals tasked with selecting appropriate components for water pressure measurement systems, ensuring that the infrastructure remains robust over time.

Durability and Mechanical Performance Metrics

When evaluating the performance of 4 core cables with vent tubes, it’s essential to consider their durability and mechanical performance metrics. Two critical parameters to assess are the breaking load and the bending radius, both of which provide insights into the physical limits of these cables and their suitability for various applications.

The breaking load refers to the maximum load that a cable can withstand before experiencing failure or breakage. This metric is vital for understanding how much stress the cable can endure during its service life. For applications involving water pressure measurement, such as in deep-water installations, the breaking load becomes crucial in determining the cable’s ability to survive extreme conditions without compromising integrity. Depending on the application, engineers should select cables that not only meet the required breaking load specifications but also offer a safety margin, ensuring long-term reliability.

Another significant factor is the bending radius, which indicates the smallest radius that the cable can be bent without incurring damage. A small bending radius may lead to kinks or compromises in the cable’s functionality. It is particularly important when routing cables through tight spaces or around sharp corners. Understanding the minimum bending radius allows for better planning in cable installation, helping to avoid inadvertent damage that could lead to costly repairs or downtime.

Í hagnýtum forritum, both breaking load and bending radius should be taken into consideration together. Til dæmis, when installing 4 core cables with vent tubes in environments where they may be subject to tension or physical constraints, both metrics will guide professionals to make informed decisions regarding cable selection and installation methods. Ensuring optimal performance under operational scenarios is foundational for effective water pressure measurements.

Conclusion and Future Perspectives

Í stuttu máli, the exploration of 4 core cables with vent tubes for water pressure measurement has revealed their critical role in ensuring accuracy and reliability. These specialized cables are designed to withstand the harsh environments typically encountered in water pressure applications, significantly elevating performance standards. Throughout this discussion, we have highlighted how the unique design elements of these cables promote effective pressure transmission, while their durability ensures a long service life even under challenging conditions.

As industries increasingly rely on precise water pressure measurements for various applications, such as hydrostatic testing, aquaculture, og umhverfisvöktun, the importance of selecting the right cable cannot be understated. The integration of vent tubes into 4 core cables plays a pivotal role in alleviating internal pressures and minimizing the risk of measurement errors. This synergy between cable design and functionality is paramount for engineers and technicians involved in water management systems.

Horft til framtíðar, advancements in cable technology are expected to yield even more robust solutions. Innovations, such as improved materials that enhance the durability and flexibility of these cables, may significantly contribute to achieving heightened accuracy in pressure readings. Þar að auki, the potential for smart cable solutions, incorporating sensors and data transmission capabilities, could revolutionize the way water pressure is monitored and managed across various sectors.

Að lokum, as we continue to advance in the field of cable technology, the prospects for new applications and improved reliability in water pressure measurement will expand. The emphasis on selecting quality 4 core cables with vent tubes will remain crucial to meet the demands of an evolving industry, ultimately leading to more efficient water resource management practices.