Inleiding tot 4 Core Cables with Vent Tubes

In recent years, 4 Kernkabels met ontluchtingsbuizen zijn naar voren gekomen als essentiële componenten op het gebied van engineering, particularly in applications related to water pressure measurement and fluid level detection. These specialized cables are designed to provide reliable and accurate measurement of various fluid parameters, which is crucial for numerous industries, including construction, environmental monitoring, and water resource management. The significance of these cables lies not only in their structural design but also in their functionality, which integrates advanced technology for enhanced performance.

The primary structure of a 4 core cable typically includes four conductors that enable the transmission of data related to electrical signals generated by pressure sensors. The inclusion of vent tubes facilitates the communication with pressure transducers in a manner that compensates for atmospheric pressure fluctuations. This design is particularly important in environments where water levels and pressures can change rapidly due to environmental conditions. As water instances are often subjected to atmospheric pressure variations, using cables with vent tubes ensures that measurements remain accurate and reliable, thus avoiding potential data inaccuracies.

These cables are extensively used in scenarios ranging from monitoring water levels in reservoirs, to managing pressure in industrial water systems. By maintaining a stable reference pressure through the vent tubes, engineers can obtain realistic measurements that inform decision-making processes. Verder, the versatility of 4 kernkabels zorgen ervoor dat ze in een verscheidenheid aan installaties kunnen worden gebruikt, van toepassingen op oppervlakteniveau tot deepwell-systemen, het vergroten van hun bruikbaarheid op verschillende technische gebieden.

Uiteindelijk, het begrijpen van de betekenis van 4 kernkabels met ontluchtingsbuizen zijn essentieel voor professionals die zich bezighouden met techniek en milieuwetenschappen, omdat deze kabels niet alleen de meetprecisie verbeteren, maar ook het effectieve beheer van en toezicht op de watervoorraden vergemakkelijken.

Waterdrukmeting begrijpen

Waterdrukmeting is een cruciaal aspect in verschillende industrieën, zoals de hydrologie, sanitair, en milieumonitoring. Het concept draait om het begrijpen van de kracht die door water wordt uitgeoefend, die de systeemefficiëntie en veiligheid aanzienlijk kunnen beïnvloeden. Pressure measurement is primarily concerned with quantifying the pressure in a water system, typically measured in pounds per square inch (PSI) or pascals (Pa). Aanvullend, accurate readings are crucial for monitoring the integrity of water delivery systems and ensuring that pressure levels remain within safe operational tolerances.

Several types of sensors are utilized for measuring water pressure, with each possessing distinct advantages depending on the application. Common sensor types include piezoresistive, capacitive, and strain gauge sensors. Piezoresistive sensors are particularly valued for their accuracy and responsiveness, making them suitable for applications requiring precise pressure measurements. Capacitive sensors offer a different approach, as they measure pressure based on changes in capacitance, while strain gauge sensors function by measuring distortion in a material under pressure. Each sensor type provides unique benefits in terms of sensitivity and reliability, allowing for tailored solutions based on specific operational requirements.

To facilitate effective data transmission from these sensors to monitoring systems, 4 core cables are frequently employed. These specialized cables consist of four conductors, which enhance communication capabilities by allowing for simultaneous transmission of multiple signals. The design of 4 core cables, often incorporated with vent tubes, ensures that any pressure variations detected by the sensor are accurately and efficiently communicated to the monitoring systems. This seamless transfer of data is essential for establishing a comprehensive overview of water pressure conditions. Accurate water pressure readings play a vital role in preventing system failures, optimizing operations, and ensuring compliance with regulatory standards across various sectors.

Importance of Vent Tubes in Cable Design

Vent tubes play a critical role in the overall functionality of 4 core cables, particularly those designed for water pressure measurement. These tubes serve as essential components that allow for accurate equalization of atmospheric pressure within the system. In setups where fluid level measurement is vital, such as in water management systems, the presence of vent tubes is crucial to ensuring that sensors and transducers can deliver precise readings.

The primary function of vent tubes is to allow air to enter the cable, which helps balance the internal and external pressures exerted on the sensing apparatus. Wanneer vloeistof stijgt of daalt binnen het meetapparaat, Er treden drukverschillen op. Zonder ontluchtingsbuizen, deze veranderingen kunnen tot foutieve metingen leiden, omdat het drukverschil ervoor kan zorgen dat de sensoren onnauwkeurig reageren. Door de druk gelijk te maken, ontluchtingsbuizen helpen deze verschillen te verkleinen, wat resulteert in betrouwbare en consistente vloeistofniveaumetingen.

Verder, ontluchtingsbuizen spelen een belangrijke rol bij het voorkomen van de opbouw van negatieve druk, die de prestaties van het drukmeetsysteem negatief kunnen beïnvloeden. In wisselende omgevingsomstandigheden, zoals tijdens hevige regenval of snelle verdamping, Het is van cruciaal belang dat de drukniveaus stabiel blijven. Ventilatiebuizen vergemakkelijken deze stabiliteit door het ontsnappen van opgesloten lucht en vocht mogelijk te maken, thereby reducing the risk of pressure-related measurement errors that may otherwise compromise the data collected.

Samengevat, the incorporation of vent tubes in the design of 4 core cables enhances the accuracy and reliability of water pressure measurement systems. By effectively equalizing pressure and preventing atmospheric interference, these tubes ensure that measurement instruments operate efficiently, even in diverse and changing environmental conditions.

Mechanical Properties and Environmental Resistance

4 core cables with vent tubes are engineered to exhibit exceptional mechanical properties, making them ideal for various applications, particularly in challenging environments such as sewer and cleaning water systems. One of the standout features of these cables is their high mechanical resistance, which allows them to withstand significant physical stress without compromising their integrity. This durability is crucial in scenarios where cables may experience abrasions or impacts from external elements, ensuring consistent performance over time.

Another key attribute of 4 core cables is their flexibility. This characteristic facilitates easier installation and routing through tight spaces, which is often a requirement in sewer systems or cleaning infrastructure. The flexibility of these cables enables them to bend and contour around obstacles, ensuring that they can be deployed in a manner that minimizes stress points and potential failure points. This adaptability is beneficial in applications where traditional cabling might not be viable due to the non-linear layouts of sewage and water systems.

Bovendien, 4 kernkabels vertonen een aanzienlijke weerstand tegen omgevingsinvloeden, wat van fundamenteel belang is in omgevingen die worden blootgesteld aan agressieve chemicaliën en wisselende temperaturen. De materialen die worden gebruikt bij de productie van deze kabels zijn ontworpen om weerstand te bieden aan corrosie en degradatie veroorzaakt door blootstelling aan giftige stoffen die vaak voorkomen in afvalwater of schoonmaakoplossingen. Als resultaat, ze behouden hun functionaliteit en levensduur, voor een betrouwbare werking, zelfs onder de meest ongunstige omstandigheden. De combinatie van mechanische sterkte en omgevingsbestendigheid maakt deze kabels een optimale keuze voor professionals die zich richten op het garanderen van efficiënte waterdrukmetingen in uitdagende omgevingen.

Elektrische specificaties en veiligheidsnormen

Bij het bespreken 4 kernkabels met ontluchtingsbuizen gebruikt voor waterdrukmeting, Het begrijpen van hun elektrische specificaties is van het grootste belang. These cables are designed to operate effectively under specific conditions, including an operating voltage typically ranging from 300V to 600V. This voltage rating ensures that the cables can handle the electrical demands common in water pressure measurement systems without compromising safety or functionality.

Another crucial specification is insulation resistance, which usually exceeds 1000 megohms at 500V DC. High insulation resistance plays a significant role in preventing electrical leakage, promoting overall system efficiency, and ensuring user safety. In addition to these core specifications, the cables often exhibit characteristics such as low capacitance, which further enhances signal integrity and reduces interference in measurement outputs.

Adhering to established safety standards is vital in the application of these cables. Kabels ontworpen voor drukmeting in watersystemen moeten voldoen aan relevante nationale en internationale veiligheidsrichtlijnen, zoals IEC 60529, die betrekking heeft op de mate van bescherming die door behuizingen wordt geboden (IP-classificaties). Zorgen voor een goede isolatie, vochtbestendigheid, en kabelintegriteit voorkomt potentiële gevaren, inclusief kortsluiting en elektrische branden.

Bovendien, deze specificaties dragen bij aan de lange levensduur en betrouwbaarheid van de kabels in veeleisende omgevingen. Bijvoorbeeld, Blootstelling aan water en andere barre omstandigheden kan inferieure producten snel aantasten. Daarom, Het kiezen van kabels met robuuste isolatie en beschermende eigenschappen is essentieel voor het behouden van de operationele effectiviteit bij waterdrukmeettoepassingen. Algemeen, a comprehensive understanding of the electrical specifications and adherence to safety standards guarantees the safe and efficient functioning of 4 core cables with vent tubes.

Core Configuration and Color Coding

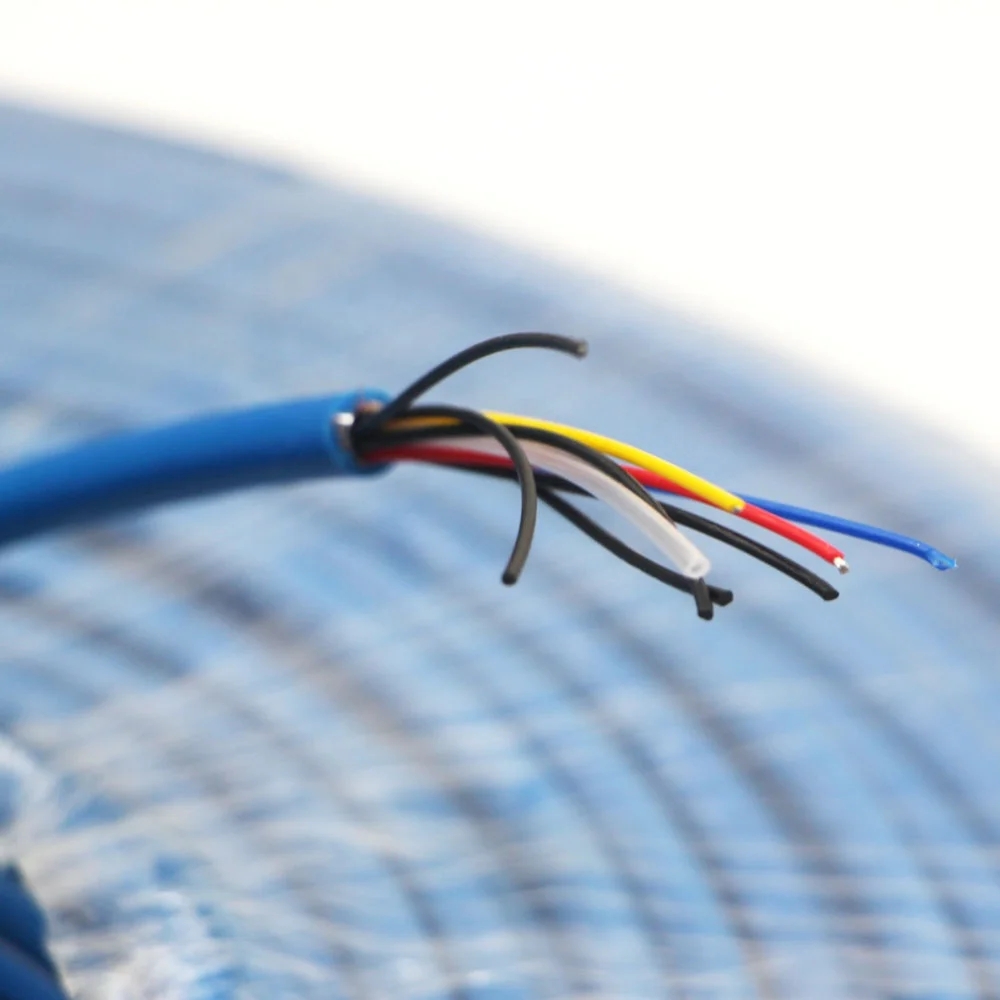

The core configuration of 4 core cables with vent tubes used for water pressure measurement plays a critical role in ensuring accurate data transmission and efficient operation of the associated sensors. These cables typically feature conductors with a cross-section that is optimized for both flexibility and conductivity. The choice of the conductor’s size impacts the cable’s electrical resistance, allowing for minimal signal loss and increased responsiveness. For effective performance, the cross-sectional area must be sufficient to carry the expected load without overheating. Dus, manufacturers often recommend specific conductor sizes based on the anticipated range of water pressure measurements.

In addition to the conductor cross-section, the color coding of the cables significantly enhances the usability and safety of these components during installation and maintenance. The standard color scheme employs four distinct colors: rood, groente, wit, and black. Each color is designated a specific function to streamline the identification process. Bijvoorbeeld, the red conductor typically correlates with positive voltage supply, ensuring that users can easily connect the cable to the appropriate terminal without confusion. Green often represents the ground connection, which is crucial for safety and the prevention of electrical shocks.

Meanwhile, the white conductor is generally utilized for sensor signal transmission, facilitating data transfer to the monitoring system. The black conductor typically serves as the negative or return path for the circuit. This systematic color coding not only minimizes installation errors but also aids technicians during troubleshooting and maintenance activities. Als resultaat, the clear identification of functions through color coding contributes to the reliability and efficiency of water pressure measurement systems. Algemeen, understanding both the core configuration and the associated color coding is essential for anyone involved in the installation or maintenance of these specialized cables.

Operating Conditions and Temperature Ranges

The operational effectiveness of 4 core cables with vent tubes largely hinges on the environmental conditions and temperature ranges within which they are deployed. Deze kabels zijn ontworpen om een breed scala aan bedrijfsscenario's te weerstaan, waardoor ze geschikt zijn voor diverse toepassingen, vooral in waterdrukmeetsystemen. Specifiek, deze kabels vertonen een opmerkelijke duurzaamheid onder extreme temperaturen die variëren van -30℃ tot 75℃. Deze veelzijdigheid zorgt voor betrouwbare prestaties in uiteenlopende omgevingen, of het nu in ijskoude buitenomstandigheden is of in relatief warme industriële omgevingen.

Het handhaven van de operationele integriteit onder dergelijke temperatuurschommelingen is van cruciaal belang voor toepassingen op de lange termijn, vooral op terreinen als milieumonitoring, industriële omgevingen, en civiele techniek. Bij temperaturen tot -30℃, de fysieke en elektrische eigenschappen van de kabels blijven intact, waardoor storingen worden voorkomen en consistente metingen worden gegarandeerd. Op dezelfde manier, at elevated temperatures up to 75℃, the integrity of the 4 core cables is preserved, allowing them to function efficiently in high-stress environments aimed at precise water pressure measurements.

Bovendien, these cables’ resistance to environmental factors such as humidity, abrasion, and chemical exposure contributes to their overall reliability and lifespan. The incorporation of vent tubes further enhances this design by preventing moisture ingress, which is crucial for maintaining the function of the underlying sensors. Als resultaat, applications involving these cables can be deployed in varied locations, including underground installations and exposed outdoor environments, without compromising performance. Understanding these operating conditions and temperature ranges is essential for professionals tasked with selecting appropriate components for water pressure measurement systems, ensuring that the infrastructure remains robust over time.

Durability and Mechanical Performance Metrics

When evaluating the performance of 4 core cables with vent tubes, it’s essential to consider their durability and mechanical performance metrics. Two critical parameters to assess are the breaking load and the bending radius, both of which provide insights into the physical limits of these cables and their suitability for various applications.

The breaking load refers to the maximum load that a cable can withstand before experiencing failure or breakage. This metric is vital for understanding how much stress the cable can endure during its service life. For applications involving water pressure measurement, such as in deep-water installations, the breaking load becomes crucial in determining the cable’s ability to survive extreme conditions without compromising integrity. Depending on the application, engineers should select cables that not only meet the required breaking load specifications but also offer a safety margin, ensuring long-term reliability.

Another significant factor is the bending radius, which indicates the smallest radius that the cable can be bent without incurring damage. A small bending radius may lead to kinks or compromises in the cable’s functionality. It is particularly important when routing cables through tight spaces or around sharp corners. Understanding the minimum bending radius allows for better planning in cable installation, helping to avoid inadvertent damage that could lead to costly repairs or downtime.

In practical applications, both breaking load and bending radius should be taken into consideration together. Bijvoorbeeld, when installing 4 core cables with vent tubes in environments where they may be subject to tension or physical constraints, both metrics will guide professionals to make informed decisions regarding cable selection and installation methods. Ensuring optimal performance under operational scenarios is foundational for effective water pressure measurements.

Conclusion and Future Perspectives

Samengevat, the exploration of 4 core cables with vent tubes for water pressure measurement has revealed their critical role in ensuring accuracy and reliability. These specialized cables are designed to withstand the harsh environments typically encountered in water pressure applications, significantly elevating performance standards. Throughout this discussion, we have highlighted how the unique design elements of these cables promote effective pressure transmission, while their durability ensures a long service life even under challenging conditions.

As industries increasingly rely on precise water pressure measurements for various applications, such as hydrostatic testing, aquaculture, en milieumonitoring, the importance of selecting the right cable cannot be understated. The integration of vent tubes into 4 core cables plays a pivotal role in alleviating internal pressures and minimizing the risk of measurement errors. This synergy between cable design and functionality is paramount for engineers and technicians involved in water management systems.

Kijkend naar de toekomst, advancements in cable technology are expected to yield even more robust solutions. Innovations, such as improved materials that enhance the durability and flexibility of these cables, may significantly contribute to achieving heightened accuracy in pressure readings. Bovendien, the potential for smart cable solutions, incorporating sensors and data transmission capabilities, could revolutionize the way water pressure is monitored and managed across various sectors.

Conclusie, as we continue to advance in the field of cable technology, the prospects for new applications and improved reliability in water pressure measurement will expand. The emphasis on selecting quality 4 core cables with vent tubes will remain crucial to meet the demands of an evolving industry, ultimately leading to more efficient water resource management practices.